Factory Photos

Nuestras Capacidades

- Precisión con una tolerancia de pieza de 0,025 mm

- Molde de múltiples cavidades

- Desenroscado del molde

- Two-shot mold

- Canales calientes de los principales fabricantes

- Prototipo de utillaje

- Overmolds

- Insert molds

- Molde de fundición a presión

- Utillaje de estampado

DFM( Design For Manufacturing)

To Save time and Save energy, it’s always necessary to provide DFM after the project is awarded, We Strongly believe good quality Mould starts from Technical Analysis and Mold Design We can also help customer to improve the part design ,and provide our professional advice to meet the manufacturing requirements.

Mold Flow

As a step in the process of shortening the lead time and avoid costly modifications due to poor design and execution,Tuo Gong is using Moldflow Mold Advisor to simulate the plastic injection molding process. In addition We conduct cooling analysis, and shrinkage & warpage analysis.

High fill pressure, short shots, high gate shear, poor cooling, long cycle times and distortion problems are quality decisive issues that can be highlighted and fixed before construction begins.

The software offers the mold designer the best reference solution to analyze the injection process before the mold is built, to determine what changes are needed and greatly reduce the tooling development lead time.

The 3D flow simulation includes:

- Fill time

- Injection pressure

- Temperature analysis

- Flow balancing

- Gate and feed system design

- Optimizing part geometry

- Optimizing and refining wall thickness

- Fiber analysis

- Gas injection simulation

By utilizing filling analysis the processing characteristics of an injection mould can be investigated and optimized at the design stage. Improvements in part quality are achieved by:

- Refining gate points

- Repositioning of weld lines

- Eliminating gas traps

- Reducing in balancing pressure

- Reducing stress levels

A mould cooling analysis is conducted to find the optimum cooling channel and layout, range for the mould surface temperature, and to simulate hot runners and inserts.

Shrinkage and warpage analysis reduces the risk of assembly problems due to inaccurate moulding. Warpage analysis is also very useful as an investigating tool for existing moulds, to find a practical solution to distortion problems.

Molding Capabilities

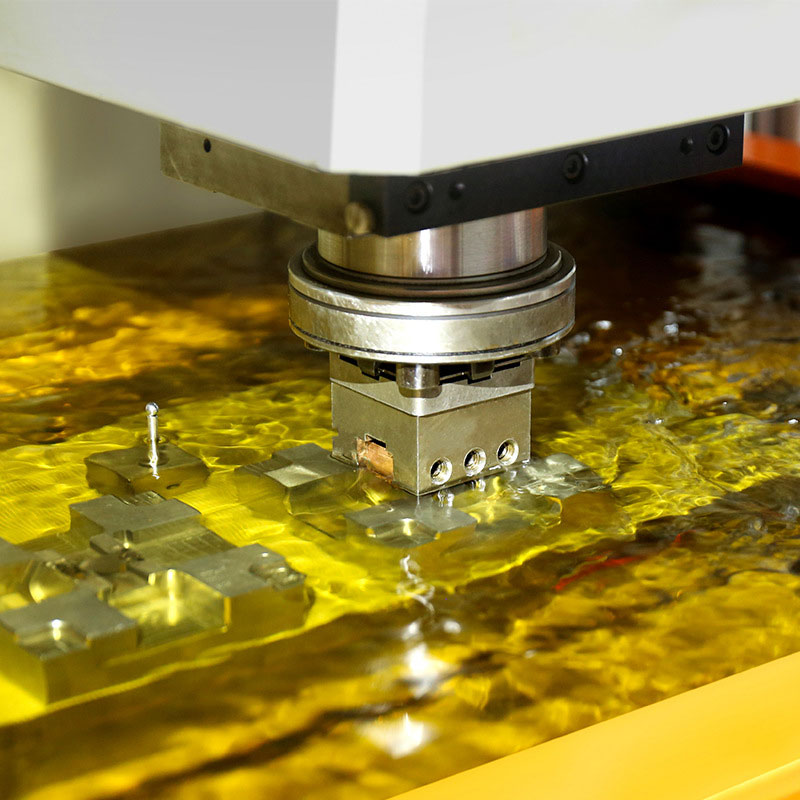

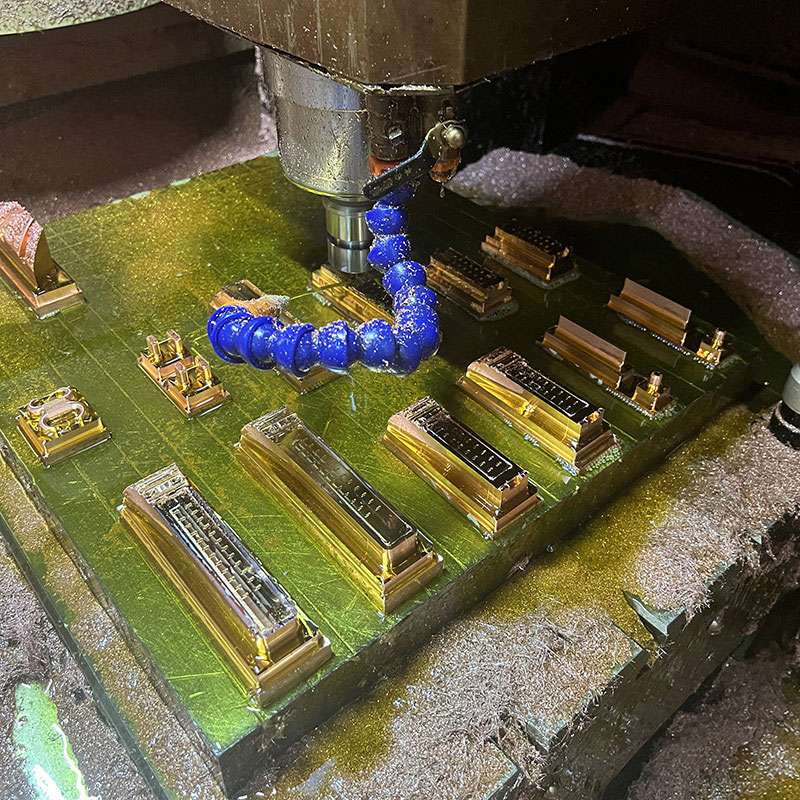

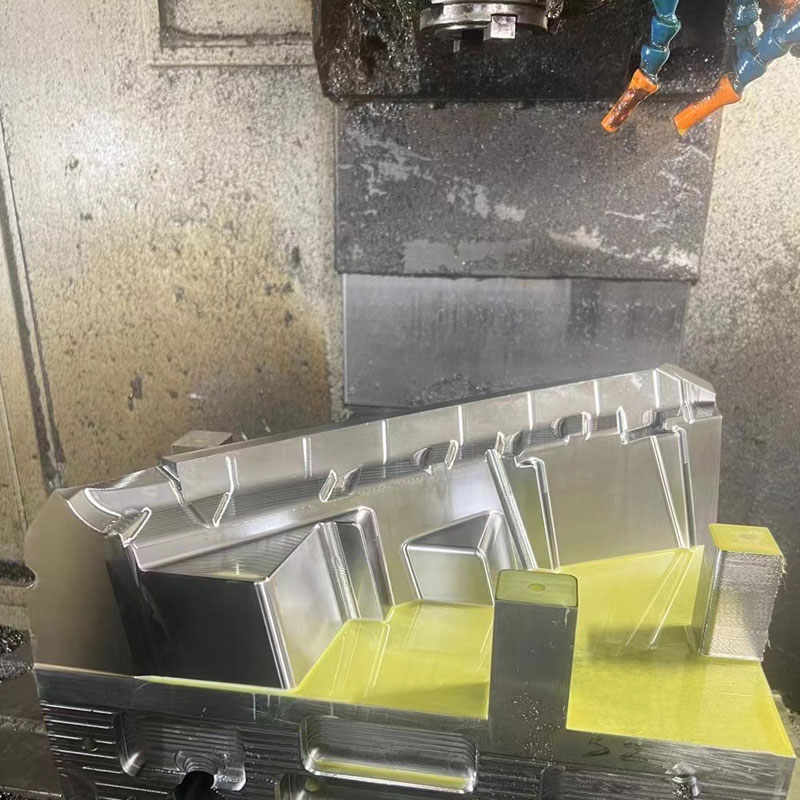

Mold Machining

Our facilities are fully equipped with “state of the art” equipments including CNC, EDM, Grinding Machines, Milling Machines. Our careful workers andproduction management systems will guarantee each part to be traceable to related technicians and machines from design to delivery. We supply fully detailed documents to meet customer’s requirements.

We used Pro/E, Mold Flow, Auto-CAD, Solidwork to meet customers different format.